breaking down rare earth element magnets for Researchers have developed a new method for recycling rare earth elements (REEs) from discarded electronics, promising a more efficient and environmentally friendly approach.

breaking down rare earth element magnets for

The Importance of Rare Earth Elements

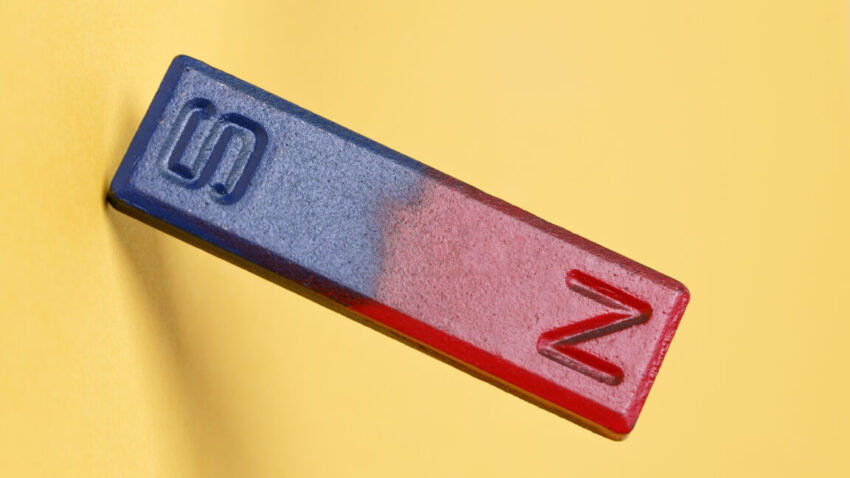

Rare earth elements are a group of 17 chemically similar elements that play a crucial role in modern technology. They are essential in the production of various electronic devices, including smartphones, laptops, and electric vehicles. As the demand for these technologies continues to rise, so does the need for REEs. However, the extraction and processing of these elements from natural sources can be both environmentally damaging and economically challenging.

Currently, the majority of the world’s supply of rare earth elements comes from mining operations, particularly in China, which dominates the global market. The extraction process is often associated with significant environmental degradation, including soil and water contamination. Additionally, the geopolitical implications of relying heavily on a single country for these critical materials have raised concerns about supply chain security.

Challenges in Recycling Rare Earth Elements

Despite the increasing awareness of the need for sustainable practices, recycling REEs from electronic waste has proven to be a complex task. Traditional recycling methods often involve labor-intensive processes that are not only costly but also generate considerable emissions and pollution. The separation of REEs from other materials in electronic waste, such as plastics and metals, is particularly challenging due to the intricate designs of modern electronics.

Moreover, the existing recycling techniques can be inefficient, leading to the loss of valuable materials. As a result, a significant amount of electronic waste ends up in landfills, where it can leach harmful substances into the environment. According to the Global E-waste Monitor, approximately 53.6 million metric tons of electronic waste were generated worldwide in 2019, and only 17.4% of this was recycled. This underscores the urgent need for innovative recycling solutions.

A Breakthrough in Recycling Technology

In light of these challenges, a team of researchers has made significant strides in developing a new method for recycling rare earth magnets, which are commonly found in various electronic devices. The research team, led by James Tour, a professor of materials science and nanoengineering at Rice University, published their findings in the Proceedings of the National Academy of Sciences.

The new method focuses on using an electric current to rapidly heat waste magnets to extremely high temperatures. This process is designed to be both energy-efficient and less polluting compared to traditional methods. By applying an electric current, the team can achieve the necessary temperatures quickly, minimizing energy consumption.

The Role of Chlorine Gas

One of the key innovations in this process is the use of chlorine gas. As the waste magnets are heated, chlorine gas is introduced to react with the non-REE materials present in the mix. This reaction keeps the non-REEs in a vapor phase, allowing for their separation from the valuable rare earth elements. The result is a more streamlined process that reduces the need for extensive chemical treatments and minimizes waste.

James Tour emphasizes that this method could significantly contribute to the United States’ efforts to meet its growing demand for rare earth elements. As the country seeks to reduce its dependence on foreign sources, particularly from China, innovative recycling techniques like this one could play a vital role in securing a stable supply of these critical materials.

Implications for the Environment

The environmental implications of this new recycling method are promising. Traditional recycling processes often involve the use of harsh chemicals and generate significant waste, contributing to pollution and greenhouse gas emissions. In contrast, the method developed by Tour and his team aims to minimize these negative impacts.

By reducing the energy required for the recycling process and limiting the release of harmful substances, this approach could help mitigate the environmental footprint of rare earth element extraction. Furthermore, as the world grapples with the challenges of climate change and resource depletion, finding sustainable ways to recycle valuable materials becomes increasingly critical.

Stakeholder Reactions

The response from the scientific community and industry stakeholders has been largely positive. Experts recognize the potential of this new method to revolutionize the recycling of rare earth elements. Many believe that it could serve as a model for future innovations in electronic waste recycling.

Industry leaders in the electronics sector are also taking note. As companies strive to adopt more sustainable practices, the ability to efficiently recycle rare earth elements could enhance their supply chain resilience. This is particularly relevant for manufacturers of electric vehicles and renewable energy technologies, which rely heavily on these materials.

Future Research Directions

While the initial results are promising, further research is needed to optimize the process and assess its scalability. Researchers will need to explore the feasibility of implementing this method on a larger scale, as well as its economic viability. Additionally, studies will be necessary to evaluate the long-term environmental impacts of this new recycling technique.

Collaboration between academia, industry, and government will be crucial in advancing this research. By working together, stakeholders can develop comprehensive strategies to address the challenges of electronic waste and rare earth element recycling. This collaborative approach could lead to the establishment of a circular economy, where materials are reused and recycled, reducing the need for virgin resources.

Conclusion

The development of a new method for recycling rare earth elements from electronic waste represents a significant advancement in the field of materials science. By utilizing electric currents and chlorine gas, researchers have created a process that is more efficient, less polluting, and holds the potential to meet the growing demand for these critical materials.

As the world continues to grapple with the challenges of resource depletion and environmental degradation, innovative recycling solutions like this one will be essential. By embracing sustainable practices and investing in research, society can work towards a future where valuable materials are conserved, and the environmental impacts of electronic waste are minimized.

Source: Original report

Was this helpful?

Last Modified: October 21, 2025 at 4:38 am

5 views