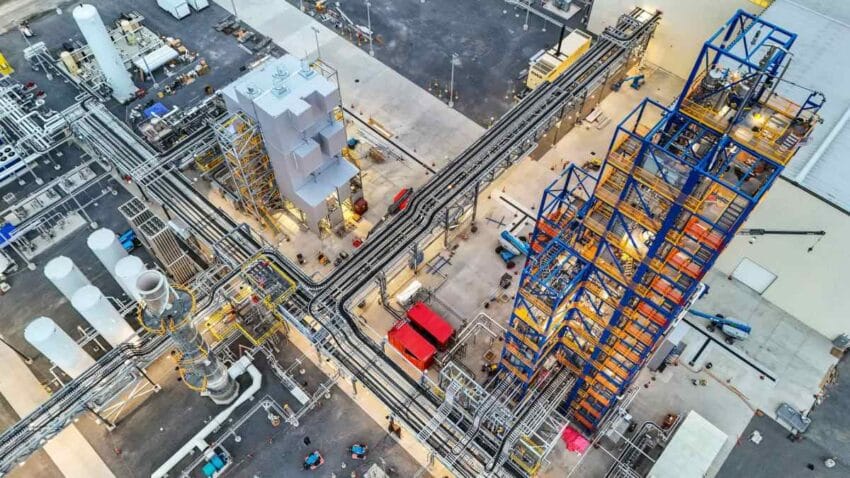

sila opens u s factory to make Sila has officially opened its new manufacturing facility in Moses Lake, Washington, marking a significant milestone in the production of silicon anodes for electric vehicle (EV) batteries.

sila opens u s factory to make

Overview of Sila’s New Facility

After nearly two years of construction, Sila’s state-of-the-art facility is set to begin volume production of silicon anodes. This development is crucial as the demand for energy-dense batteries continues to rise, driven by the increasing adoption of electric vehicles and the need for sustainable energy solutions. The new factory is expected to play a pivotal role in enhancing the performance and efficiency of EV batteries, which are essential for the transition to greener transportation.

Significance of Silicon Anodes

Silicon anodes represent a significant advancement over traditional graphite anodes used in lithium-ion batteries. While graphite has been the standard material for decades, it has limitations in terms of energy density and overall battery performance. Silicon, on the other hand, has the potential to store much more lithium, which can lead to batteries that are not only lighter but also capable of holding more energy.

According to Sila, their silicon anodes can increase the energy density of batteries by up to 20% compared to conventional graphite anodes. This increase in energy density translates to longer driving ranges for electric vehicles, a crucial factor for consumer adoption. As automakers strive to produce vehicles with greater range and efficiency, the demand for silicon anodes is expected to grow significantly.

Investment and Economic Impact

The establishment of the Moses Lake facility is a part of Sila’s broader strategy to scale up production and meet the growing demand for advanced battery materials. The company has invested heavily in this project, with significant funding aimed at not only building the facility but also ensuring it is equipped with cutting-edge technology for efficient production.

This investment is likely to have a positive economic impact on the local community. The factory is expected to create hundreds of jobs, ranging from manufacturing positions to engineering and research roles. This influx of jobs can stimulate the local economy and contribute to the development of a skilled workforce in the region.

Broader Industry Context

The opening of Sila’s facility comes at a time when the EV market is experiencing rapid growth. According to industry reports, global electric vehicle sales are projected to surpass 26 million units by 2030, a significant increase from previous years. This surge in demand is prompting manufacturers to seek innovative solutions to improve battery technology and reduce costs.

As competition intensifies, companies like Sila are positioning themselves as leaders in the battery materials sector. By focusing on silicon anodes, Sila aims to differentiate itself from competitors who are still relying on traditional materials. The company’s commitment to innovation aligns with broader trends in the industry, where sustainability and efficiency are becoming paramount.

Technological Innovations

Sila’s manufacturing process for silicon anodes incorporates advanced technologies that enhance the performance and scalability of production. The company has developed proprietary methods to create silicon-based materials that are not only efficient but also cost-effective. This innovation is crucial for making silicon anodes a viable option for mass-market electric vehicles.

One of the key technological advancements is Sila’s ability to produce silicon anodes that maintain structural integrity during the charging and discharging cycles. Traditional silicon anodes tend to expand and contract significantly, leading to degradation over time. Sila’s technology mitigates these issues, resulting in longer-lasting batteries that can withstand the rigors of daily use.

Partnerships and Collaborations

To further bolster its position in the market, Sila has formed strategic partnerships with several leading automakers and battery manufacturers. These collaborations are designed to integrate Sila’s silicon anode technology into next-generation battery systems. By working closely with industry leaders, Sila aims to accelerate the adoption of its innovative materials and ensure compatibility with existing battery technologies.

Such partnerships are essential in an industry where the pace of innovation is rapid. By aligning with established players, Sila can leverage their expertise and resources to enhance its product offerings and expand its market reach. This collaborative approach not only benefits Sila but also contributes to the overall advancement of battery technology.

Environmental Considerations

As the world shifts towards more sustainable energy solutions, the environmental impact of battery production is under scrutiny. Sila is committed to minimizing its carbon footprint and ensuring that its manufacturing processes are environmentally friendly. The company has implemented several initiatives aimed at reducing waste and energy consumption in its production facility.

Moreover, the use of silicon anodes can contribute to more sustainable battery technologies. By increasing energy density, Sila’s products can help reduce the number of batteries needed for electric vehicles, thereby decreasing the overall environmental impact associated with battery production and disposal.

Future Prospects

Looking ahead, Sila’s new facility in Moses Lake positions the company for significant growth in the coming years. As demand for electric vehicles continues to rise, the need for advanced battery materials will only increase. Sila’s focus on silicon anodes places it at the forefront of this evolving market.

In addition to electric vehicles, there is potential for Sila’s technology to be applied in other sectors, such as consumer electronics and renewable energy storage. The versatility of silicon anodes makes them an attractive option for a variety of applications, further expanding Sila’s market opportunities.

Stakeholder Reactions

The opening of the Moses Lake facility has garnered positive reactions from various stakeholders, including industry experts, local government officials, and environmental advocates. Many view this development as a step forward in the quest for sustainable energy solutions.

Local government officials have expressed enthusiasm about the job creation and economic benefits that the facility will bring to the region. The prospect of new employment opportunities and investment in the community is seen as a positive development for Moses Lake and surrounding areas.

Industry experts have also highlighted the significance of Sila’s advancements in battery technology. The ability to produce energy-dense silicon anodes could revolutionize the electric vehicle market, making EVs more accessible and appealing to consumers. This shift is crucial for meeting global climate goals and transitioning to a more sustainable future.

Conclusion

The opening of Sila’s manufacturing facility in Moses Lake, Washington, marks a pivotal moment in the evolution of battery technology for electric vehicles. With its focus on silicon anodes, Sila is poised to make a significant impact on the industry, offering solutions that enhance energy density and efficiency. As the demand for electric vehicles continues to grow, Sila’s innovations will play a crucial role in shaping the future of sustainable transportation.

Source: Original report

Was this helpful?

Last Modified: September 23, 2025 at 3:37 pm

2 views