ifixit takes a closer look at the iFixit has released an in-depth analysis of Apple’s innovative 3D printing techniques, specifically focusing on the USB-C port of the newly announced iPhone Air.

ifixit takes a closer look at the

Introduction to 3D Printing in Consumer Electronics

3D printing has emerged as a transformative technology in various industries, including consumer electronics. This manufacturing process allows for rapid prototyping, customization, and the ability to produce complex geometries that traditional methods cannot achieve. Apple has been at the forefront of this technology, recently unveiling its 3D printing techniques for the Apple Watch Series 11 and Ultra 3. Following this announcement, iFixit conducted a thorough examination of Apple’s 3D-printed components, particularly the USB-C port in the iPhone Air.

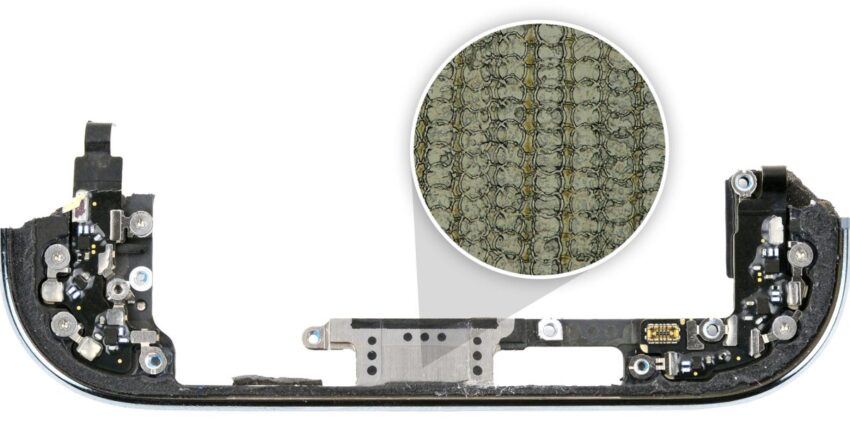

iFixit’s Findings on the iPhone Air’s USB-C Port

iFixit’s analysis reveals several key insights into the design and functionality of the iPhone Air’s USB-C port, showcasing Apple’s commitment to innovation and efficiency in manufacturing.

Design and Structure

The USB-C port in the iPhone Air is notable not only for its functionality but also for its intricate design. iFixit highlighted that the port is constructed using advanced 3D printing techniques that allow for a high degree of precision. The use of 3D printing enables Apple to create a port that is both lightweight and robust, meeting the demands of modern users who require durability in their devices.

Material Composition

One of the standout features of the 3D-printed USB-C port is its material composition. iFixit noted that Apple has utilized a specialized polymer that enhances the port’s resistance to wear and tear. This choice of material is crucial, as USB ports are often subjected to frequent plugging and unplugging, which can lead to degradation over time. The polymer used in the iPhone Air’s USB-C port not only improves longevity but also contributes to the overall aesthetic of the device.

Manufacturing Efficiency

The 3D printing process employed by Apple significantly streamlines manufacturing. Traditional methods of producing components like USB ports often involve multiple steps and the use of various materials, which can be time-consuming and costly. In contrast, 3D printing allows for the creation of the entire port in a single process, reducing the number of steps required and minimizing waste. This efficiency is particularly important for Apple as it aims to meet high consumer demand while maintaining its commitment to sustainability.

Implications for Future Devices

The insights from iFixit’s analysis raise important questions about the future of 3D printing in consumer electronics. As Apple continues to refine its manufacturing processes, it is likely that we will see more components produced using 3D printing technology in upcoming devices.

Potential for Customization

One of the most exciting implications of 3D printing is the potential for customization. As consumers increasingly seek personalized devices, the ability to create unique components on demand could revolutionize the way products are designed and manufactured. Apple’s exploration of 3D printing opens the door for tailored solutions that cater to individual user preferences, enhancing the overall user experience.

Environmental Considerations

Apple has long been committed to sustainability, and the adoption of 3D printing aligns with this ethos. The reduction of waste in the manufacturing process, along with the use of recyclable materials, positions Apple as a leader in environmentally responsible production. As the company continues to innovate, it is likely that we will see further initiatives aimed at minimizing the environmental impact of its products.

Stakeholder Reactions

The announcement of the 3D-printed USB-C port in the iPhone Air has garnered a range of reactions from stakeholders, including industry experts, consumers, and environmental advocates.

Industry Experts

Industry analysts have praised Apple’s move towards 3D printing, noting that it could set a precedent for other manufacturers. The ability to produce high-quality components more efficiently may encourage competitors to explore similar technologies. This shift could lead to a broader adoption of 3D printing across the electronics sector, fostering innovation and competition.

Consumer Feedback

Consumer reactions have been largely positive, with many expressing excitement about the potential for increased durability and customization. The USB-C port’s design has been well-received, with users appreciating the blend of functionality and aesthetics. However, some consumers have raised concerns about the long-term reliability of 3D-printed components, emphasizing the need for thorough testing and quality assurance.

Environmental Advocates

Environmental advocates have welcomed Apple’s efforts to incorporate 3D printing into its manufacturing processes. The reduction of waste and the use of sustainable materials align with the growing demand for eco-friendly practices in the tech industry. However, some advocates urge Apple to continue prioritizing transparency in its supply chain and manufacturing processes to ensure that sustainability claims are substantiated.

Challenges Ahead

While the advancements in 3D printing are promising, there are challenges that Apple and other manufacturers must navigate as they integrate this technology into their production lines.

Quality Control

Ensuring the quality and reliability of 3D-printed components is paramount. As the technology evolves, manufacturers must develop rigorous testing protocols to guarantee that products meet safety and performance standards. Any lapses in quality control could undermine consumer trust and lead to potential safety issues.

Cost Considerations

Although 3D printing can reduce manufacturing costs in the long run, the initial investment in technology and training can be significant. Companies must weigh the benefits against the costs to determine the feasibility of adopting 3D printing at scale. For Apple, balancing innovation with profitability will be crucial as it navigates this transition.

Conclusion

iFixit’s exploration of the iPhone Air’s 3D-printed USB-C port highlights the potential of 3D printing to revolutionize the consumer electronics industry. With its emphasis on design, efficiency, and sustainability, Apple is positioning itself as a leader in this emerging field. As the company continues to innovate, the implications for future devices, customization, and environmental responsibility will be significant. Stakeholder reactions indicate a mix of optimism and caution, underscoring the importance of quality control and cost considerations as Apple moves forward in its 3D printing journey.

Source: Original report

Was this helpful?

Last Modified: November 20, 2025 at 9:39 am

13 views